- Home

- SUMO-SS-DEF-DROP-ARM-CONV-KIT - Defender Drop Arm Conversion Kit, Stainless Steel by Gwyn Lewis

SUMO-SS-DEF-DROP-ARM-CONV-KIT - Defender Drop Arm Conversion Kit, Stainless Steel by Gwyn Lewis

Special Order (Typically Dispatched Within 5-7 Business Days)

Part Number: SUMO-SS-DEF-DROP-ARM-CONV-KIT

From£184.00(Exc VAT)

From£220.80(Inc VAT)

Product Information

This conversion uses one of our STAINLESS STEEL Steering Bars, (SUMO-SS) they are 30mm solid 303 Stainless Steel bar, these bars are the strongest in the sumobars range as stainless offers a much greater strength, it is 1.5 times stronger than steel, these bars can be used from on road to extreme off road use.

When fitting the SUMO LOCK NUTS onto the track rod ends use plenty of grease on the threads, this will prevent the nuts seizing onto the track rod ends, (cold welding) or (Galling) this is common with stainless steel fixings, but use plenty of grease will prevent the problem from happening.

This is a conversion kit to change the standard Defender Swan Neck Drop Arm to a Straight Drop Arm from a Discovery 1 300tdi.

Benefits:-

- This is a much better Drop Arm for a Defender as it eliminates the press in ball joint that is used in a Defender’s Swan Neck Drop Arm and replaces it with a normal Track Rod End.

- The Defender press in ball joints can be very difficult to replace, a normal Track Rod End is much easier to replace.

- The Defender press in ball joints do not last very long before they start to show wear and play, a Track Rod End lasts much longer, the Track Rod Ends we use are Greaseable which lasts even longer.

- The Rubber Boots on Defender Swan Neck Drop Arms pop off quite easily allowing dirt and water into the joint causing premature wear, Track Rod End Boot does not pop off.

- Our Heavy Duty Steering Bars can give your steering a more solid feel, standard steering bars do flex quite easily.

Picture 3 shows the two different Drop Arms, the lower one is the Straight Discovery Drop Arm that is included in our kit, as you can see it uses a track rod end and not a press in ball joint that is difficult to replace.

If you are finding it difficult to remove your original drop arm with a puller, you can see in one of the pictures where a customer has cut a slot in the drop arm, it will then pull off much easier.

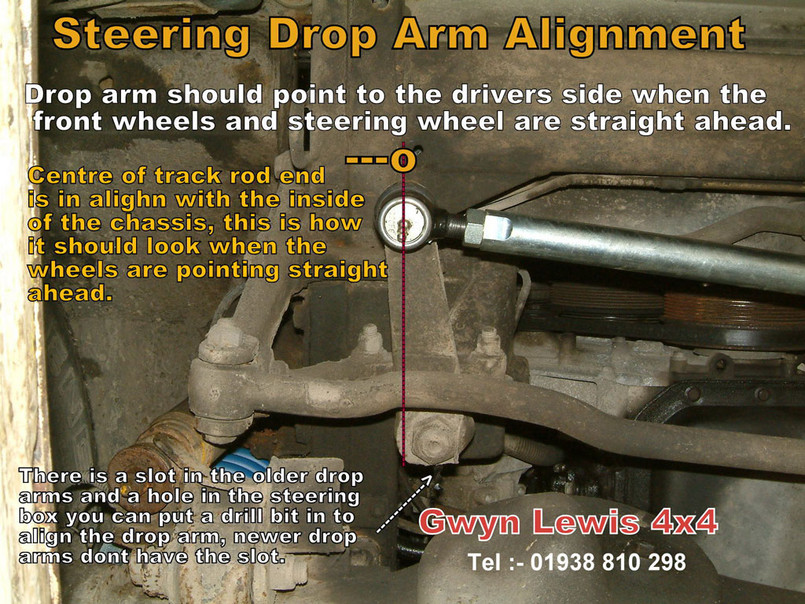

See the last picture showing how to align the drop arm once fitted, it is master splined so cannot be fitted in the wrong position on the splined shaft from the steering box. The drop arm should point slightly towards the driver’s side when driven in a straight line, also make sure you tighten and re check the nut that secures the drop arm to the steering box, this needs to be checked at least a couple of times after use due to the splined taper on the steering box.

The Torque Setting of the Drop Arm securing nut is 176 NM, it is VERY IMPORTANT that the tightness of this nut is rechecked after use.

Once you are satisfied the Drop Arm has fully worked up the tapered spline of the steering box and the nut remains tight you can then knock over the edges of the lock washer.

FAQ's

If you have any questions about this product or any of the products in our range, please contact us on sales@lrparts.net or contact our main centre on: 0151 486 0066.

Delivery

Our delivery is very easy. We use flat rate fees across all our orders and this is calculated at the checkout. In some cases and normally with International orders we may not be able to calculate delivery fees automatically. Our system will allow you to order the products with free delivery, so you can guarantee the stock / order items. Our team will obtain the best and most price economical quote from a range of delivery suppliers and email you a link to our site to pay for delivery.

Have a question?

Contact Us